Mot de passe oublié ?

PLUM ENGAGEMENT

PLUM COMMITMENT

As an industrial company, we are aware of our impact on the environment, and we were aware of this long before we started producing fasteners. That's why, from the outset of our history, we have always favored approaches that preserve natural resources and respond to today's environmental concerns.

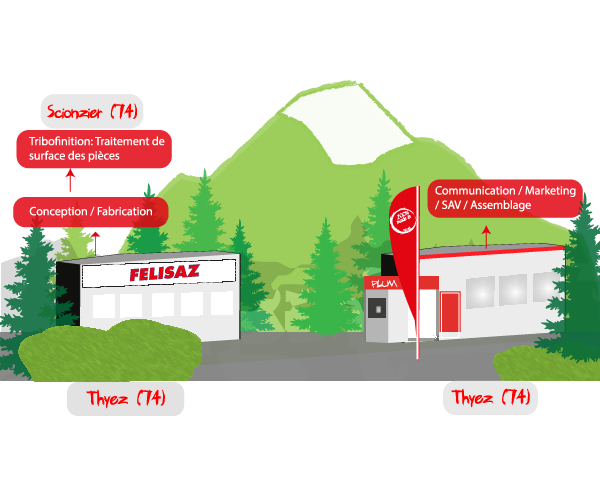

Our company is located in THYEZ in the Arve Valley, a valley renowned for its exceptional Alpine setting and dynamic industrial activities. Today, unfortunately, it's its high levels of air pollution that are the talk of the town. We are deeply affected and concerned by the environmental consequences of our region's economic activities. This pollution is the direct result of heavy road traffic, high consumption of wood-burning fuels and industrial pollution.

At Plum, we're all passionate about mountains and nature, which is why we're committed to producing our bindings while minimizing our impact on the environment we hold so dear. This starts with our “Made in France” business model: by working with the local economy, we favor short circuits and minimize the distance between our intermediaries.

Did you know that importing a product into France generates 58% more CO2 emissions than a product made in France*?

We advocate “100% made in France” manufacturing, but we go even further in our approach by seeking out intermediaries in the Arve Valley and extending the circle to the Rhône-Alpes region. This not only limits travel distances, but also enables us to work with local players.

AGEC law

AGEC law

As part of the French Anti-Waste for a Circular Economy Act (AGEC), we are committed to improving the environmental transparency of our products and practices through 4 main initiatives :

Environmental responsibility

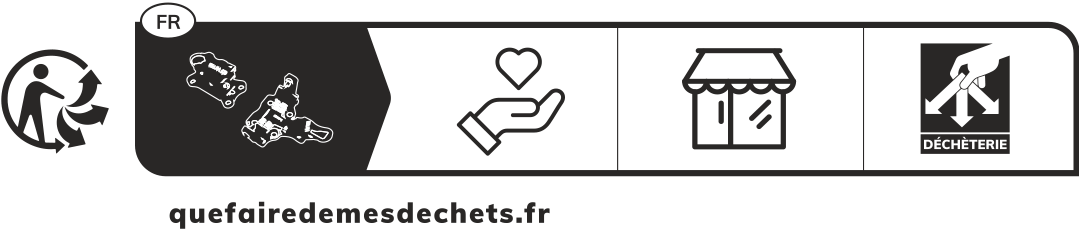

Our products are currently subject to an Extended Producer Responsibility (EPR) scheme, which means that we integrate the principles of the circular economy into our design and production processes. We favor the use of recyclable materials, and the design of our products contributes to their reparability in order to extend their lifespan, as well as to their end-of-life transformation by facilitating the dismantling and sorting of the materials used.

Repairability

Our fasteners are designed to last. Although they are not covered by the reparability index, we promote maintenance by making spare parts available on our website, as well as technical advice for professionals and private individuals.

We systematically favor repairing an existing fastener rather than replacing it prematurely.

We refrain from any form of programmed obsolescence, whether in our design choices or in our choice of high-quality materials.

Recyclability

We work to maximize the recyclability of the materials we use. Our fasteners are mainly made from metal alloys and engineering plastics, for which recycling channels exist. End-of-life products can be entrusted to sorting centers or landfill sites equipped to process metals and plastics.

We regularly offer incentives for customers to bring in their fasteners for replacement with a newer model. This enables us to repair the bindings we take back and put them back into use, so as to extend their lifespan and make them accessible to as many people as possible.

Éco-design

In our eco-design approach, we seek to :

- Minimize the mass of raw materials used,

- Extend product life by choosing robust materials,

- Actively combat all forms of programmed obsolescence.

- Reduce the environmental impact of machining and manufacturing,

- Promote short supply chains by prioritizing production in Haute Savoie, France and Europe.

We're looking for eco-responsible alternatives

We're looking for eco-responsible alternatives

----------------------------------------------------------------------

----------------------------------------------------------------------

As with any economic activity, we are aware of the impact our activity can have on the environment. We are constantly seeking alternatives and more eco-responsible solutions in our production, without impacting the quality of our products.

--------------------------------------------------------------------------------------------------------------------

Recycling waste materials

-

-

----------------------------------------------------------

All our Plum & Plumsplitboard bindings are machined directly from 7075 aluminum. Aluminum has proven its worth in the aeronautics industry, and is now the benchmark for quality and strength. In addition to the technical advantages of this material, our choice of aluminum over plastics enables us to recycle waste materials downstream from our activity.

Our method of production (machining in the mass) produces a high level of aluminum waste. However, unlike plastics, aluminum is 100% recyclable. Aluminum has the characteristic of being infinitely reusable, while retaining its properties and physico-chemical qualities. Aluminum scrap is cleaned, melted down and transformed into raw material, before being reused in the manufacture of various aluminum articles. This reuse of aluminum requires 95% less energy than its extraction from ore alone. Recycling one tonne of aluminium saves 6.89 tonnes of CO2, compared with 1.53 tonnes of CO2 for plastic.

In addition to the aluminum scrap we produce, we sometimes have scrap parts with certain defects that make them unusable. We give a second life to some of these parts. For example, defective locking levers or heel rests can be transformed into key rings. To see our PLUM key rings, click here!

Solubles recycling

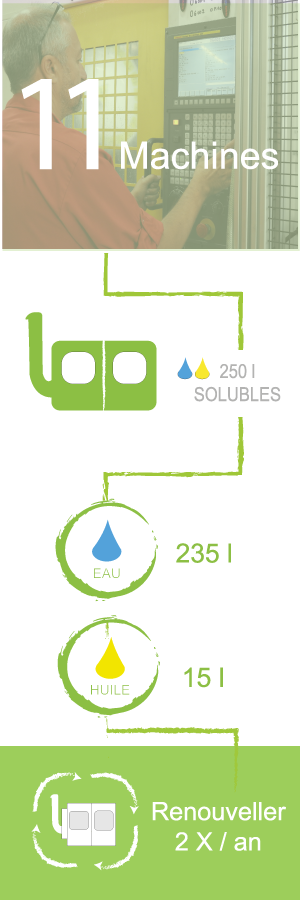

In our production, we also seek the best solutions for recovering and processing the soluble waste associated with our activity.

Each of our machines uses 250 liters of solubles per year, i.e. 15 liters of lubricant and 235 liters of water. A change twice a year enables us to minimize our consumption. Some of our machines run on oil and, depending on their characteristics, consume between 60 and 200 liters of oil, which we change once a year. Used oil waste is either centrifuged and reused, or sent to a cement plant for energy recovery.

After leaving the machines, the chips are conveyed and collected in a chip bin. The swarf storage area is equipped with a drip tray to catch any liquids mixed with the swarf and containing pollutants.

We subcontract the processing of used oils and solubles: The drums of liquids to be treated are collected.

The installation of a rainwater recovery tank enables us to operate our EDM cutting machine (which runs on demineralized water).

Green all the way

For our skis and splitboards, we also call on local expertise, choosing “Les shapers alpins”. Based in Marignier, this local company specializes in the manufacture of skis and snowboards. By choosing to use Greenpoxy resin to manufacture its skis and boards, the company has opted for a more respectful production method.

Composed of 35% plant-derived carbon molecules, this resin derived from tree bark offers an ecological and responsible alternative to chemical resins. When we tested our products made from this natural resin, we were won over by the quality and performance it offered in terms of lightness and versatility.

It was only natural that we should support “Les shapers alpins” in their approach by modifying the structure of our products and opting for this cleaner but equally high-performance formula. To find out more about the composition of greenpoxy resin, click here!

PLUM textiles "Made in France"

In the same spirit, we have chosen local suppliers to produce our 100% Made in France textile range. Our PLUM overalls, headbands and PLUM & PLUMSPLITBOARD chokers are all made in FRANCE. Our sweatshirts are made entirely in Passy, Haute-Savoie, just a few kilometers from the company. Made from 50% polyester, 50% Spanish cotton (CCE), there was no question of compromising on material quality. Find our PLUM & Plumsplitboard sweatshirts click here!

All aware, all responsible...

All aware, all responsible...

------------------------------------------------------------

We see ecology as a way of life and are constantly striving to improve our practices, right down to our premises. The entire PLUM team is committed to taking responsibility, in particular by making changes in our day-to-day practices.

Our employees seek to reduce individual travel by walking, cycling, taking public transport or carpooling to and from work.

Until now, each employee used several plastic cups a day. Not an insignificant habit when you consider that for an average of 2 cups per employee/day, we were throwing away a total of 14,400 cups/year. Plastic cups, which contain toxic substances, take several decades to disappear into nature. Aware of the consequences of this bad consumption habit, PLUM has decided to eliminate the use of plastic cups since June 2017 (coffee machines, water fountain, refectory...). Now every PLUM employee has a stainless steel cup preserved from any substance risky to health and the environment. @kleAncanteen is an ethical, responsible company committed to finding more sustainable solutions.

Energy consumption in the company :

-----------------------------------------------------------

Installing a heat pump allows us to limit our energy consumption throughout the year, with heating in winter and air conditioning in warmer periods. In winter, we use the waste heat from the compressor and machinery to heat our buildings. Conversely, the heat pump enables us to air-condition the offices by evacuating the heat from the compressors to the outside. The design of our PLUM premises also limits the use of lights on a daily basis. Numerous wall openings and roof windows allow us to take advantage of natural light, thus limiting our daily electricity consumption.

All premises are equipped with garbage cans for sorting paper (blue garbage cans), plastic (yellow garbage cans) and other waste (gray garbage cans).

Plastics, cardboard and polystyrene are collected once a month by recycling companies.

We recycle used cardboard by integrating it into our logistics.

Depending on the condition of the cartons we receive, they will be :

- reused for shipping customer orders

- sorted and recycled.

On the other hand, we prefer to use unprinted cardboard packaging to limit ink use and over-packaging. Internally, our printer cartridges are refillable, which also reduces packaging waste.

Strong social values:

Strong social values:

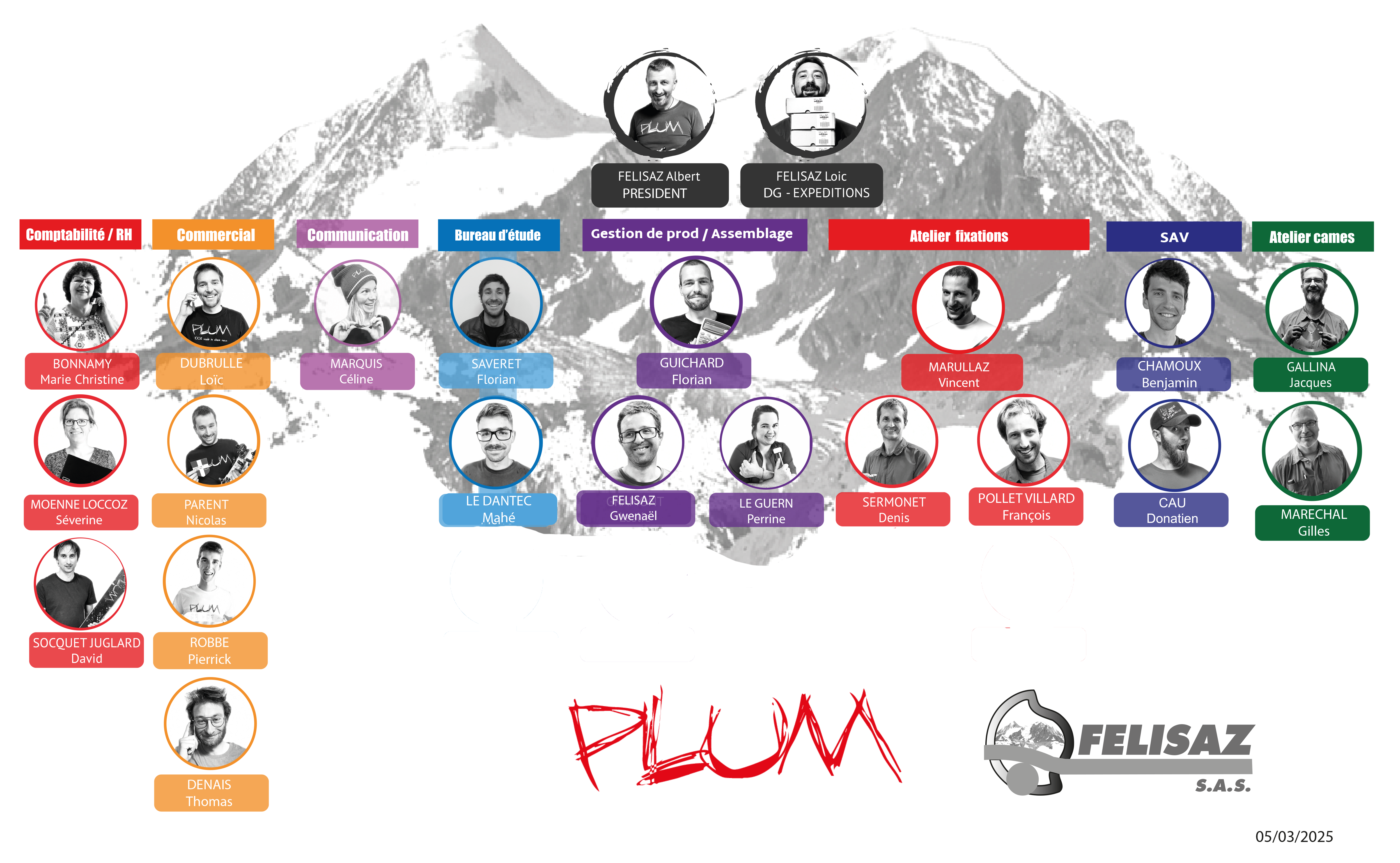

PLUM's economic activity provides a livelihood for some thirty employees.

PLUM is a company on a human scale, with strong values of sharing, exchange, quality and respect. The small size of our structure facilitates communication between the various departments (design office, sales/communication, assembly and workshop), enabling the company to be part of an ongoing evolutionary process. PLUM makes a point of developing team cohesion and offering quality working conditions to its employees.

Source:

* (ecoemballage.fr)